Pulsation absorber with damping disc for reciprocating compressors

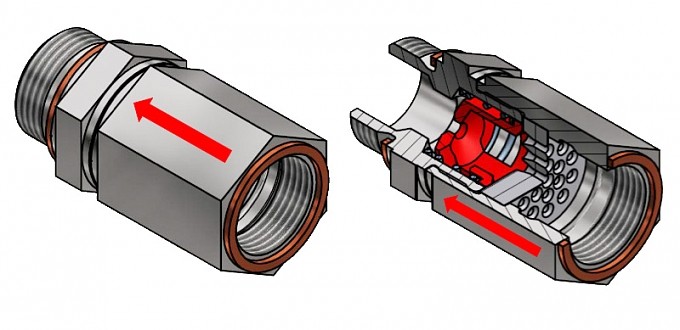

Mode of operation of the Pulsation absorber with damping disc for reciprocating compressors

Tasks:

a) Damping of the push out pulsation of reciprocating compressors, to avoid a damaging effects, e.g. Atomization of air dryer granules.

b) Reducing of the harmful effects of sudden pressure drops, e.g. dynamic component stress.

Solution:

a) Damping of the push out pulsation:

The effect of the standard pulsation damping valve (PDV) is based on the deflection (3 x 90 °) of the delivered pressure air at the valve piston. A part of the pulsation energy is converted into heat by friction in the deflections (dissipative damping).

The installed damper disc (DS) (located in flow direction before the valve piston), reduced the push-out pulsation by up to 80%. The effect of the damper disc (DS) is based on reflection and dissipation. The DS acts as a reflection point within the pipeline. The propagation of the pressure pulsation into the downstream system is prevented by reflection of the pulsation energy, at the same time "standing waves" in the pipeline are destroyed. Due to the increased flow-mechanical friction in the holes of the DS, this has simultaneously a dissipative effect. During the through-flow of the bores, pulsation energy is converted into heat by friction of the molecules, so that the pulsation is again reduced.

b) Pressure sink:

In addition to reducing of the push out pulsation from the reciprocating compressor, the upstream installed parts are protected against suddenly pressure drops, by the installed valve piston, which is closing by sudden pressure drop. Example: Suddenly pressure drops occur by the system-induced switching of the adsorption air dryer (switching over of dryer cartridges drying/regenerating and dewatering). The upstream system does not recognize the pressure drop; it works like a stationary mode.

Suddenly pressure drops means an increased component stress (dynamic load).

By using of PDV’s the life time of thin-walled components, e.g. Cooler and filter, can be significantly increased.

Due to the durability of the used materials against aggressive Medias as well as the wear resistance, the pulsations absorber is maintenance-free1).

A periodic inspection/maintenance like a pressure vessel or filter is not required.

1) Maintenance free:

Requirement to the gas: Purity (solid impurities) Degree of filtration 99.9% (5μm)

Risk assessment:

a) Frost / freez:

Permissible installation position à vertically or horizontally. The following downstream pipe must be led incline to the condensate outlet in order to avoid cumulate of the water. Water bags should generally be avoided.

In operation, as well as in the unpressurized state, the valve is open by the spring force, so that any condensate can flow off in the direction of the incline. If the valve piston is freeze with the damper disk, or the valve housing, the warm compressed air can still flow through and defrosted the valve.

At a horizontal installation and cumulating of water under the valve piston, a sufficient residual cross-section is always free as a passage for the compressed air.

b) Corrosion:

All components are made of stainless materials (1.4301)

c) Compression spring

Permanently designed

Note:

Pulsation damping valves, size 200-1,500 l / min have been on the market since 2001.

The internal piston has no a guide with the outer housing, it is guided by the pressure spring. The valve seat is self-centering.

These valves are installed on, among other things, on pressure air systems for Russia, which have been verified up to -50 ° C.

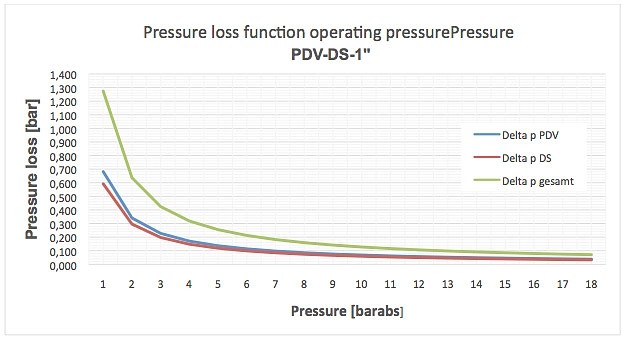

Pressure loss:

Example PDV-DS 1 "

The basis for the measurement was an oil-free 2-stage piston compressor for railway application, suction volume flow 2,100 l / min @ 8-10 bar

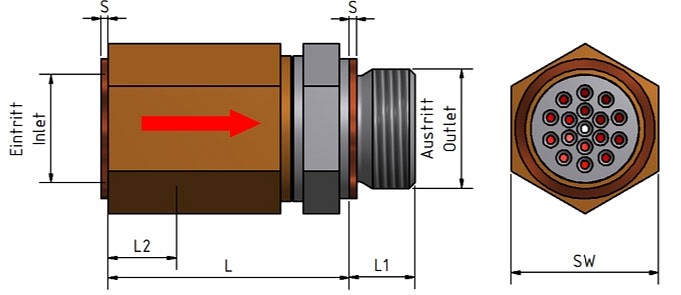

Sizes, dimensions and weights:

|

1) Volume flow |

L [mm] |

2)Outlet

|

2)Inlet

|

L1 |

L2 |

S |

SW |

Weight |

|

100 - 1000

|

53 |

M 22x1,5 |

M 22x1,5 |

14 |

14 |

1,5 |

32 |

0,3 |

|

53 |

G ½“ |

G ½“ |

14 |

14 |

1,5 |

32 |

0,3 |

|

|

< 1000 – 2500 |

67 |

G 1“ |

G 1“ |

18 |

18 |

2 |

41 |

0,5 |

|

< 2500 – 4000 |

70 |

G 1 ¼“ |

G 1 ¼“ |

20 |

20 |

2 |

46 |

0,6 |

Materials:

Housing, piston, pressure spring : Stainless steel

| 1) Volume flow rate based on | Temperatur | 20°C |

| Pressure: | 1 bar (760Torr) | |

| Medium: | Air | |

| 2) Inch thread DIN ISO 228-1 |

Manual for the:

- Pulsationsdämpfungsventil (PDV)

- Pulsationsdämpfungsventil mit Dämpferscheibe (PDV-DS)

- Pulsationsdämpfungsventil mit Bypass (PDV-BP)

Click here to download the manual (german) (PDF)

pulsmin GmbH

Hans Luette

Seelhofstraße 24

D- 79539 Lörrach

Tel.: +49 (0) 7621 169976

Fax.: +49 (0) 7621 170520