Mode of operation of the Pulsation damper for screw.- multicell compresors

The advantages of the pulsmin pulsation dampeners:

Short list of the advantages

- eliminates the cause of problems

- maintenance-free

- simple and cost-effective

- space-saving and cost-effective installation

- low component stress through dynamic stress

- more environmentally friendly due to reduced oil discharge

- aves compressed air > saves energy

Advantages of the pulsmin pulsation damper for you

Substantially increases operating life of de-oiling elements by achieving virtually stationary operation

- less stress on compressor components due to virtually stationary operation

- no contamination of the dryer and the pipeline network through entrainment of oil

- no unplanned cleaning costs for the compressed air network

- maintenance intervals for the compressor are no longer determined by oil losses

- maintenance intervals for the compressor can be planned and calculated

- drastic reduction in oil consumption (residual oil see information from compressor manufacturer)

- simple retrofitting of damping valve

- low retrofitting costs

- no sensitive electrical components, no wiring

- pulsation damping valve is not a service part (install and forget)

- longer operating life of desiccant

- stable pressure dew point as active surface of desiccant remains oil-free

- no environmental damage from oil being discharged with dryer condensate

- component cooling (condensation) from expansion of compressed air is shifted from compressor to pulsation damping valve

- lower emulsification in compressorsaves compressed air = energy (dependent on volume and level of the pressure sink)

Application of the pulsmin pulsation dampers

- extremely simple mode of operation

- low material stress (small stroke and small acceleration force)

- use of non-corroding materials:

casing- stainless steel

control piston- stainless steel

pressure spring- stainless steel - pressure spring designed to have fatigue strength for dynamic load profile

- no soft gaskets (embrittlement)

- self-centring valve seat

- secure guidance of control piston (no fretting, no fretting corrosion)

- no service parts (install and forget)

- can be mounted in any position

Compressed air production:

To maintain oil circulation, oil cooling and oil separation, all compressor types with oil-injection cooling require a corresponding periphery with oil reservoir, oil cooler, and de-oiling filters for de-oiling the compressed air.

The weak point:

The de-oiling of the compressed air is carried out with a filter element. The process of oil separation requires as even a flow as possible through the filter section.

Rapid changes in pressure and volume lead to undesirable side effects such as drastically increased residual oil content or severely reduced service life because of destruction of the filter element.

The cause:

As a result of the reduction in volume, the air drawn in is nearly 100% saturated with moisture at the compressor outlet. To avoid corrosion and freezing in the compressed air network, the air must be dried downstream of the compressor. In the mobile field of application (trams, buses), the compressed air is usually dried by using single-chamber or double-chamber adsorption dryers, or, more rarely, membrane dryers.

a) Adsorption dryer 1):

Dryers based on this principle use a constant proportion of the compressed air to regenerate the desiccant. Systemic switching operations (reversal of the container functions drying/regenerating and condensate discharge cycle) also require large quantities of compressed air for short periods of time. The cycle times for this are pre-programmed at ca. 50 seconds or 4 minutes. In the case of intermittent compressor operation, when the compressor stops the pressure line between the compressor and the dryer outlet is abruptly discharged, to allow restarting of the compressor at atmospheric pressure.

b) Membrane dryer 1):

In contrast to the adsorption dryer, the drying process here takes in air at a continuous rate of flow. The intermittent compressor operation means that air is supplied in sudden bursts, however. Whenever the compressor stops, the pressure line up to the outlet of the membrane dryer is abruptly discharged, to allow a restart at atmospheric pressure.

The physics:

The buffer volume between compressor and dryer in the form of a short compressed air line is relatively small. The intermittent peaks in the dryers need for compressed air lead, each time, to a sudden and drastic drop in pressure.

A pressure sink arises and spreads at the speed of sound towards the compressor. The compressed air present in the compressor casing expands explosively to the low level of the pressure sink, via the de-oiling/filtering element.

The damage:

As a rule the air flows through the degreasing/filter element from inside to outside. When air flows evenly through the filter section, extremely small droplets of oil coagulate to bigger and bigger drops of oil.

When they reach the outer surface, the oil drops are collected in the sump of the filter casing as a result of gravity separation, and are channelled back into the oil circulation system of the compressor.

Gaseous components remain in the compressed air.

The oil separation is, due to the operating principle, linked with a small permanent loss of pressure.

Through the pressure sink adjacent to the outer surface of the filter, a sudden increase in this pressure differential occurs. The pressure differential leads to extreme stress in the oil-soaked filter fleece. The oil adhering to the surface of the filter fleece is, in the first moment, flung off the surface explosively as a result of the pressure pulse and carried away by the compressed air. The residual oil content rises accordingly. The alternating pressure differentials wear down the filter fleece to the point of tearing. The service life is considerably reduced.

The solution: The pulsmin pulsation damper

The Pulsmin team has developed valves which can be used wherever machines or system components are jeopardized by intermittent flow rates.

Pressure irregularities caused by loads or processes are transformed into virtually constant pressure by the installation of a pulsation damping valve.

When the pulsation damping valve is closed, an integrated bypass prevents discharging of the compressor-side safety valve. The integrated bypass bore is dimensioned in such a way that back pressure corresponding to the desired operating pressure is built up.

1) Attention: mounting location for pulsation damping valve:

Adsorption dryer: upstream of the dryer, in the pressure line to the dryer or in the compressed air inlet nozzles on the dryer

Membrane dryer: downstream of the dryer, in the outlet line or directly at the compressed air outlet, in any case upstream of the relief valve.

See also diagram of adsorption dryer (PDF) and diagram of membrane dryer (PDF)

Operating Manual for Pulsation damper

Click here to download the manual (german) (PDF)

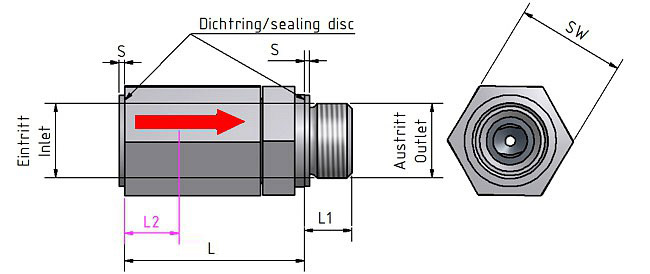

Dimension Sheet of the pulsmin pulsation dampers

|

1) Volume flow [ltr/min] |

L [mm] |

2) Outlet

|

2) Inlet

|

L1 [mm] |

L2 [mm] |

S [mm] |

SW [mm] |

Weight [kg] |

|

100 - 1000

|

53

|

M 22x1,5 |

M 22x1,5 |

14 |

14 |

1,5 |

32 |

0,26 |

|

53

|

G ½“ |

G ½“ |

14 |

14 |

1,5 |

32 |

0,26 |

|

|

< 1000 - 2500 |

67

|

G 1“

|

G 1“

|

18 |

18 |

2

|

41 |

0,5 |

|

< 2500 – 4000

|

70 |

G 1 ¼“ |

G 1 ¼“ |

20 |

20 |

2 |

46 |

0,6 |

Material: Housing, piston, compression springs: stainless steel

| 1) Volume flow rate based on | Temperatur | 20°C |

| Pressure: | 1 bar (760Torr) | |

| Medium: | Air | |

| 2) Inch thread DIN ISO 228-1 |

pulsmin GmbH

Hans Luette

Seelhofstraße 24

D- 79539 Lörrach

Tel.: +49 (0) 7621 169976

Fax.: +49 (0) 7621 170520